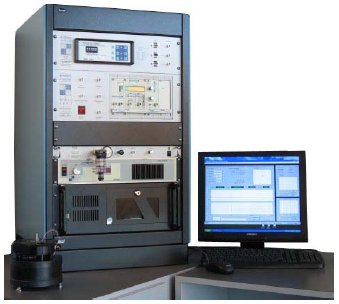

- 가속도계, 가속도센서 검교정 시스템 (Model 9155D)

- 가속도계, 가속도센서, 충격센서, 임펙터헤머 검교정 시스템입니다.

The Accelerometer Calibration Workstation Model 9155 features accurate back-to-back comparison calibration of ICP (IEPE), and charge mode piezoelectric accelerometers in accordance with ISO 16063-21(2003). The 9155 system can also calibrate piezoresistive, capacitive, and velocity sensors via available options. Other configurations offer automated TEDS sensor updating, linearity checking, low frequency calibration down to 0.1 Hz, shock calibration, and a host of shaker options.

- 마이크로폰 검교정 시스템 (Model 9350C)

- The Precision Acoustic Calibration Workstation Model 9350C is an automated, accurate, turnkey, PC-based system that features costeffective calibration of 1/8", 1/4", 1/2" and 1" microphone cartridges (opencircuit sensitivity), microphone cartridges with preamplifiers (closedcircuit sensitivity), as well as microphone Frequency Response Function.

In addition, the system provides for conformance testing of microphone preamplifiers and acoustic calibrators: this includes pistonphones as well as speaker phone based calibrators.

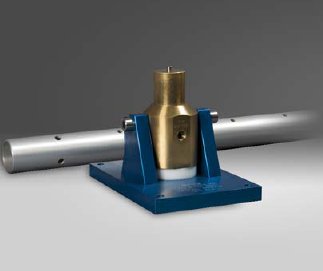

- 압력센서 검교정 시스템 (Model K9913C)

- The Dynamic Pressure Calibration System features accurate dynamic calibration of pressure sensors over a mid pressure range (150 to 100,000 psi) using a stable tourmaline reference sensor. A pressure impulse is simultaneously applied to both the reference and sensor under test (SUT) to determine the sensitivity of a pressure sensor at a particular amplitude.

By varying the amplitude level, the linearity of the SUT can also be determined. using a high quality data acquisition system

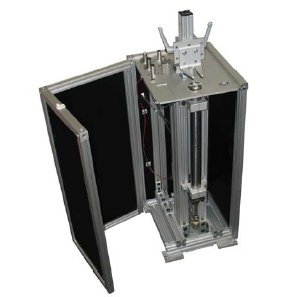

- 충격 가속도센서 검교정 시스템 (Model 9525C)

- The PneuShock Model 9525C provides shock inputs for accurate and consistent sensitivity calibrations at high acceleration levels.

1) Easy amplitude linearity calibration of shock and crash sensors from 20 g to 10,000 g

2) Controlled and consistent impacts using state-of-the-art pneumatically actuated exciter

3) Easy refinement of impulse shape and frequency content using a wide variety of impact anvils

4) Superior impact control through drive pressure and duration control

5) Precise adjustment of impact through use of digital pressure gauge

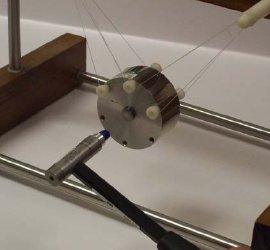

- 임팩트해머 검교정 시스템 (Model 9155D-961)

- The Hammer Calibration system allows users to quickly and easily calibrate their instrumented impact hammers and account for tip inertia or extender mass. Hammer calibration is performed by impacting a pendulous mass instrumented with a calibration accelerometer.

1. Quickly and accurately determines the sensitivity of impact hammers with various tip configurations

2. Conforms to industry-approved standards and handbooks

3. Includes verification hammer for control and regular system validation

4. Provides customizable, ISO 17025 compliant calibration certificates

HOME

HOME

1

1